The Evolution of Brick Continues

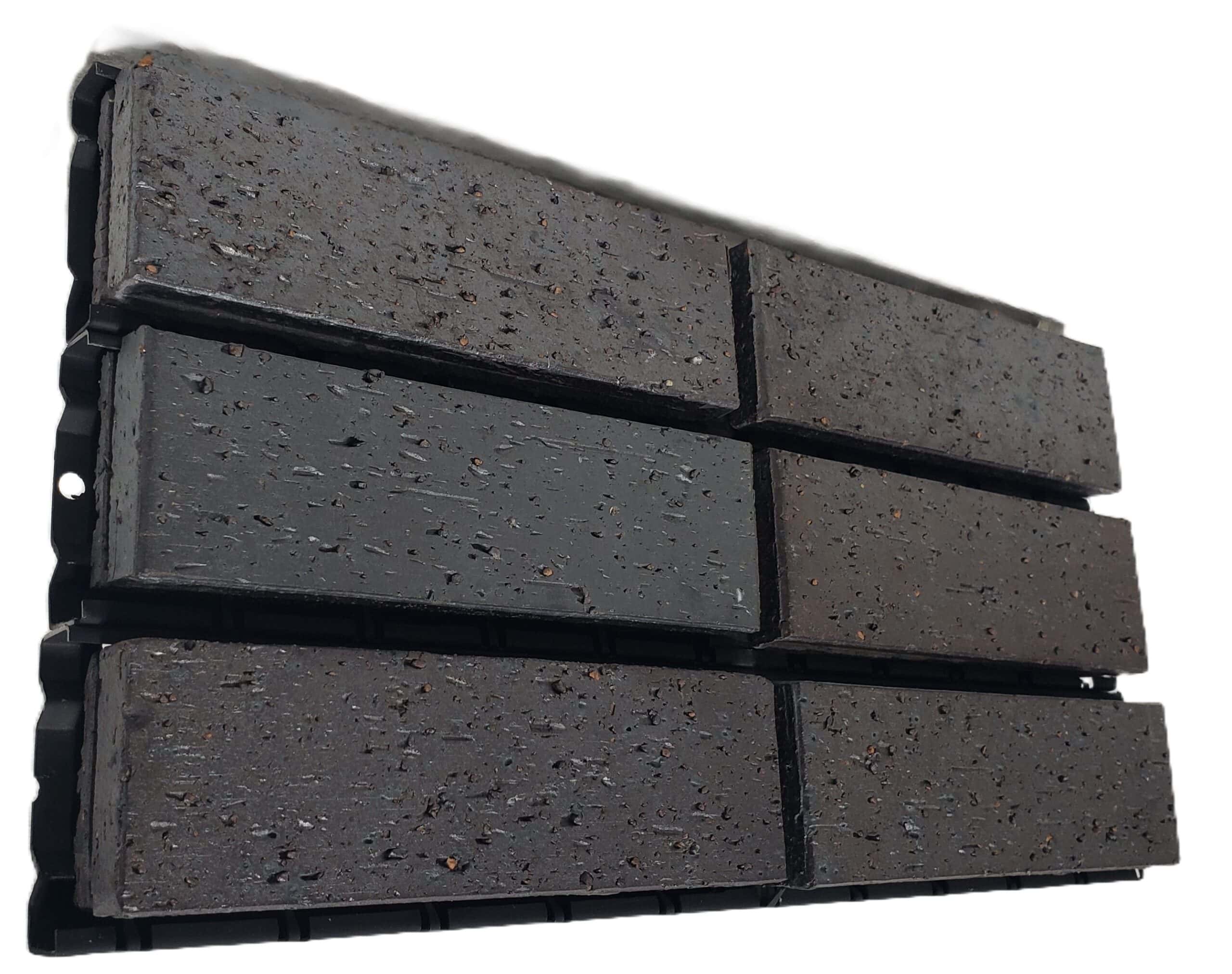

From structural brick to single wythe, with flashings, ties, relieving angles, netting, weeps, and cavity wall construction, today’s brick continues its march forward with fully engineered thin brick rainscreen assemblies that provide higher performance, are easier and quicker to install, meet the latest energy codes, and are designed to last the life of the wall.

Brooklyn, NY

The Leader in thin brick systems for more than a decade.

Desana engineered and introduced the first mechanically attached thin brick systems (Corium & Tru-Brix) to the North American market. Desana is pleased to be the industry’s pioneer, pushing the envelope of brick rainscreen design, research, and installation. Each of our systems is designed and manufactured to meet the project’s performance requirements, aesthetic considerations, and budgetary objectives.

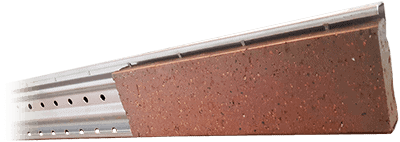

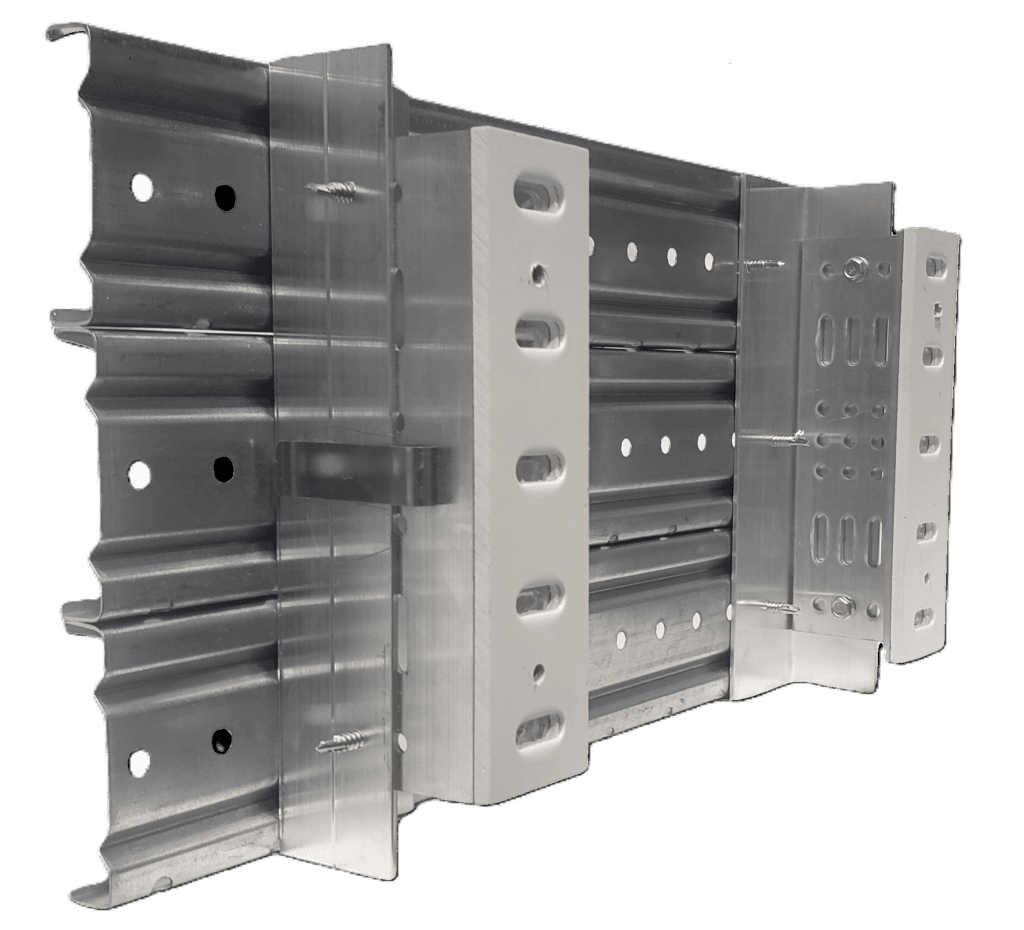

The DURUS System

Patent Pending Unique Tray Design by Desana

Desana Partners has been designing and supplying

brick rainscreen assemblies for more than a decade in North America.

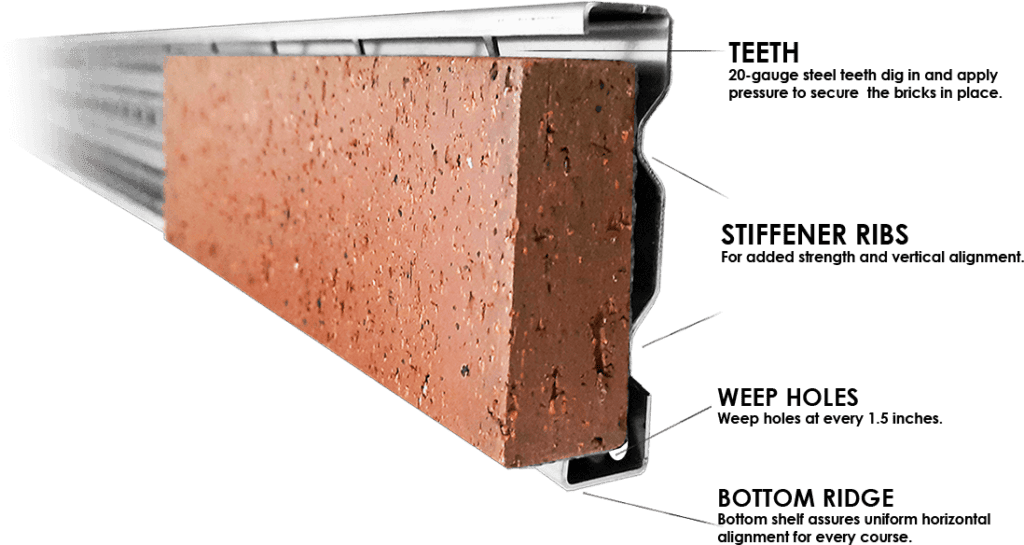

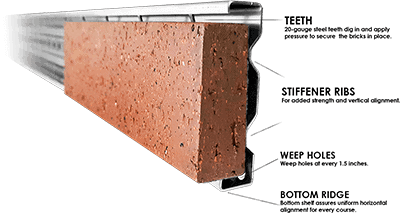

Stainless Steel DURUS trays are a benchmark of performance in brick trays.

- 20-gauge 304B stainless steel eliminates all concerns regarding corrosion or rust. With the use of stainless steel, the owner and architect assure that this thin brick assembly will last the life of the building.

- Not every project requires, and not every budget can carry, stainless steel. DURUS trays are also available in Galvalume and ZAM galvanized as well providing options and choices for each project.

- Weep holes are standard across the backside lower edge assuring all incidental moisture can easily escape and run down the back of the trays and through the cavity.

- Unique and patented tooth design accepts and secures PCI bricks from multiple sources including Belden, Endicott, Metro, Summitville, Taylor Clay, Glen Gery, and more without the premiums associated with cutting or kerfing of the bricks.

- Stiffener ribs and uniform tray base design reinforce the structural strength of the tray and serve as guides to assure vertical and horizontal alignment of every brick. The spacing between each tray can be adjusted if necessary to help align with rough openings in the wall.

Dedicated Water Management

Water and water moisture will get past the brick and mortar in our system as well as every other brick veneer assembly. The issue is where does it go once it enters the façade assembly. Every DURUS tray has a series of drainage holes @ 1” on center, to assure no pooling or ponding of water. A 2” air space between the backside of the trays and the insulation allows incidental moisture to freely drain out from the system. Continuous convention air flow keeps the cavity and the system components dry and free from moisture, protecting the continuous insulation and air/moisture barrier.

The DURUS System is a fully engineered thin brick veneer system with rear ventilation, open cavity, and water management.

At 12lbs. per square foot this system is lighter, quicker and easier to install and meets all of the latest energy codes including ASHRAE 90.1 and latest stretch code adaptations.

The system will last as long as the wall is upright.

Our Partners

Case Studies

Monroe Hall, located on the picturesque campus of Loyola University in New Orleans, underwent a transformative exterior renovation designed by Holly & Smith and constructed...

Located in the heart of Cambridge, MA, 101 Cambridge is a five-story, 160,000-square-foot mixed-use building designed by Torti Gallas and built by Consigli Construction. Featuring...

River House, located in Bridgewater, MA, is a remarkable project that demonstrates the seamless integration of brick and wood-frame construction. Designed by Embarc Studios and...