The Standard DURUS™ System

Desana Partners has nearly a decade of experience providing and developing rainscreen systems.

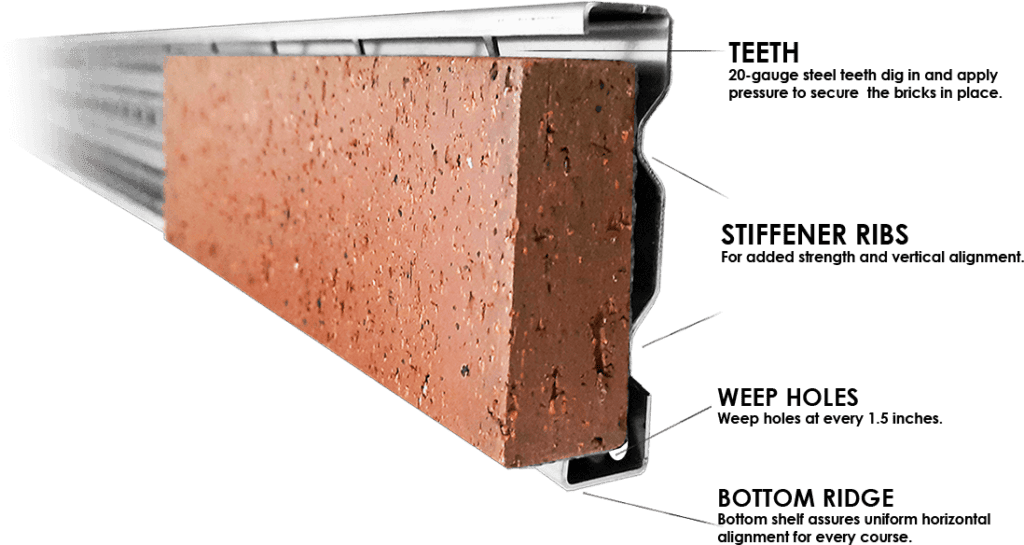

The DURUS Systems Begin with a Patent Pending Unique Tray Design

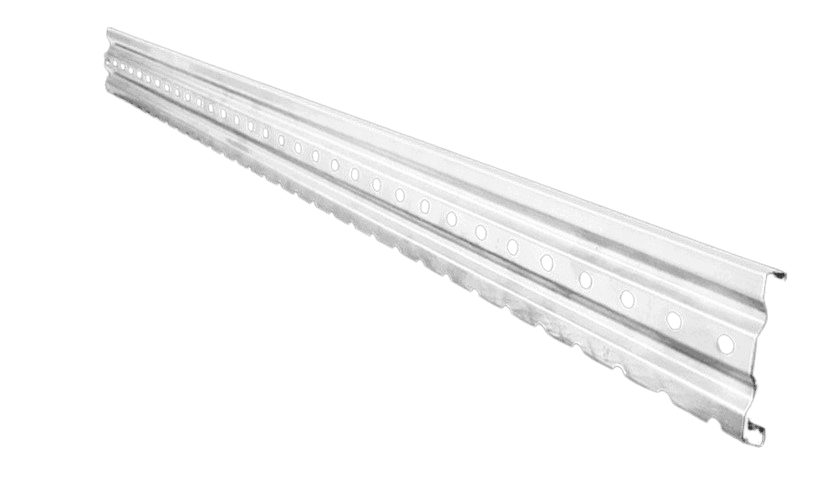

Stainless Steel DURUS trays mark a new era of performance in brick trays.

- 20-gauge 304B stainless steel eliminates all concerns regarding corrosion or rust. With the use of stainless steel, the owner and architect assure that this brick assembly will last the life of the building. DURUS trays are also available in Galvalume and ZAM galvanized as well as providing options and choices for each project.

- Weep holes are standard across the backside lower edge assuring all incidental moisture can easily escape and run down the back of the trays and through the cavity.

- Unique and patented tooth design captures and secures bricks from multiple sources including Belden, Endicott, Metro, and more without all of the costly customizing of the bricks.

- Stiffener ribs and uniform tray base design reinforce the structural strength of the tray and serve as guides to assure vertical alignment and horizontal alignment. The spacing between each tray can be adjusted if necessary to help align with rough openings in the wall.

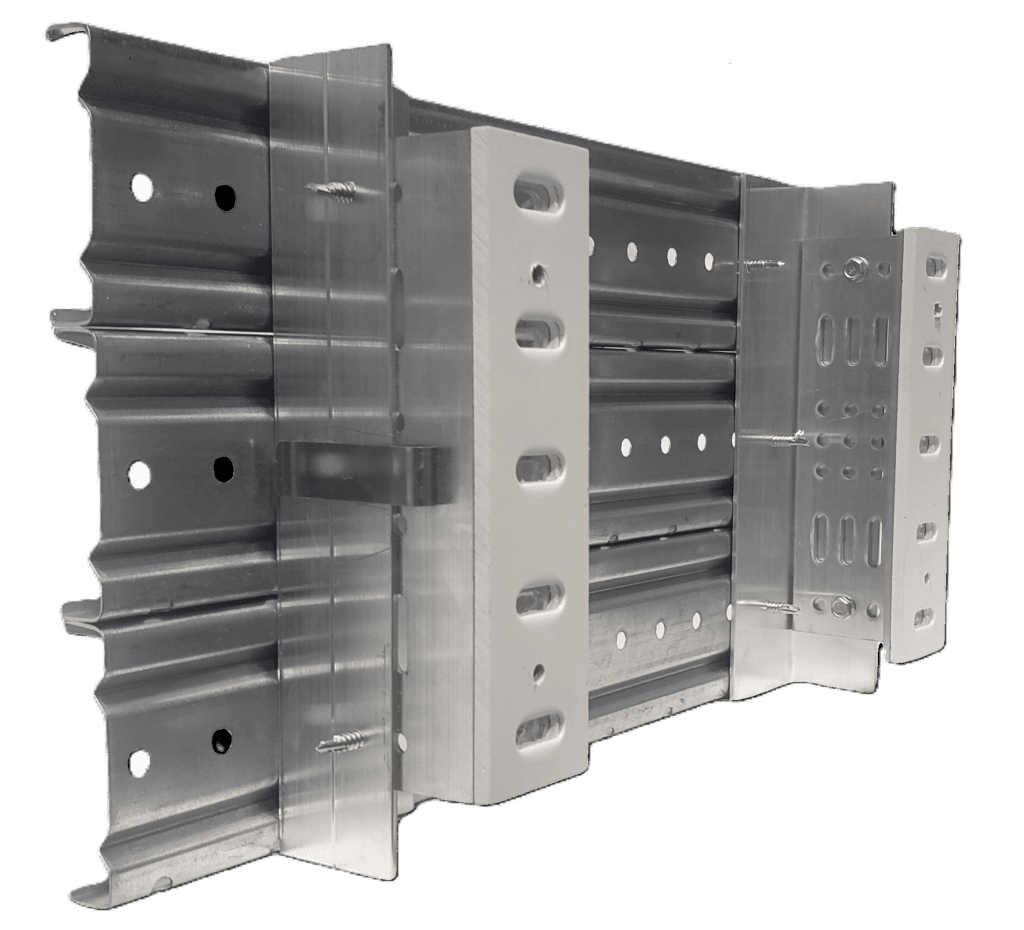

Rainscreen Assembly and Water Management

Water and water moisture will get past the brick and mortar in our system as well as every other brick veneer assembly. The issue is where it goes once it enters the façade assembly. Every DURUS tray has a series of drainage holes at 1” on center, to ensure no pooling or ponding of water. A 2” air space between the backside of the trays and the insulation allows incidental moisture to freely drain out from the system. Continuous convention airflow keeps the cavity and the system components dry and free from moisture, protecting the continuous insulation and air/moisture barrier.

Galvanized Options

DURUS trays from Desana Partners are also available in G90 galvanized steel. They are produced according to ASTM A653, which is the specification for sheet steel, zinc coated, using the continuous hot dipped process. This is a widely used process to coat sheet steel prior to fabrication. The coating produced by continuous galvanizing is uniform, has sufficient ductility to withstand deep drawing or bending without damage to the coating, and consists almost entirely of pure zinc.